Wednesday, June 5, 2013

Feedback

Constructing such a project like also has some of the hardships and its very challenging in different terms. Pain and tiredness influenced the journey and it sometimes weakens the try in looking for help. It took exactly four weeks to find an appropriate project to do but this failure never stop us from searching and searching until we have an idea but that idea also comes with a problem. The idea was gratefully appreciated but then a vehicle or engine that has a de-cat pipe must be present. This was what being required for the project a de-cat pipe instead of a catalytic convertor. Challenges of overcoming the problem arise always determine us to take a move every time. Finally we met the kind supervisor who then brainstorm and equipped us with the next step to take by showing us a (1uz engine) which is from a V8 engine with the help through the availability of the Unitec for our group to use. But these were not the only problems; it then followed another difficulty that is the presence of the materials needed for the work. Thus we work on a throttle body, so the materials are much needed in the implementation of the project, however a weakness is being identified on what we have to work on is that it’s fragile on high temperature operation.

The project struggle in terms of the assistance to make it through, the materials to use, but also looking for the expertise and the capability of the installers and those who will help us out in the construction of the de-cat pipe or welding the flap between the straight pipe. The expert helpers must be paid for the assistance they lend and it’s a must to take into consideration. Regardless of the hardships encountered throughout the project’s implementation, courage and teamwork managed to make everything possible.

The project imparts various lessons that really help us to face different circumstances in life. Tough and demanding but it may exhibit new methods and competitive ideas that are appropriate with the demand to the new technologies today.

Thursday, May 30, 2013

Industrial Issues

Exhaust system has an effect over the people as well. Due to some of the information’s being collected and bind together from a study, it examines the high risk of death caused by an unhealthy environment and this believed to be the gasses in the atmosphere. Instead of identifying the real cause of the death, still it relate to the emissions in the air as being suggested by some of the death certificates. Here are some of the contributing factors to the death of people

Carbon monoxide-

As to the year 1998, an estimation of death rate was about 200 people and this was because of vehicle generated carbon monoxide. Although some of the victims were under alcohol influence, but it was not a moving car that caused the problem.

Backing up Vehicles-

In comparison to other sources, the same information is cited that the death is caused by vehicles in enclosed space. This leads to a high estimation of victims in the young age or say less than five years old, even the age over 70 died and count up to about 6,000 minor injuries from the same incident.

Passenger compartment excessive heat inside.

In accordance to a project report of the deaths in 1998, nationally it marks up a number of 29 deaths annually being occurred because of the heat inside a vehicle passenger compartment. Comparing to the past year 1997, it gives out 27 deaths from the same incident and there is no big difference with the records of the following year.

Vehicle Window-

Thus, number of people died in 1997 and 1998 analyses the same amount of death as it has four the other years and so as for the following year. The death is caused by the collision of widows form the other vehicle to the other vehicle. A proof of the information is record in each year’s certificates.

Wednesday, May 29, 2013

National Issues

The impact of de-cat exhaust pipe installation not only influenced globally but also nationally. Healthy environment nurture healthy people and vigorous lifestyle. In the United States of America, it amended a Clean Air Act so that every car buyers, every manufactures should be informed of the various terms and conditions about the changes in the automotive repairs and servicing industry. These changes include either any part or component or used vehicle is being sold out or on offered where it has a principal effect to bypass, defeat or render inoperative any emission control device or element of design of any emission control system, expansion of the tampering that include private individuals as well as prohibiting against manufactures.

Manufacturing Regulations

Guidelines and policies are being established to sustain and maintain the appropriateness of the installation and the manufacturing of exhaust repair system in the automotive industry. These regulations involve the change in installing catalytic convertor as it is illegal under the Clean Air Act, but in order to do so, proper installation and replacement should be managed.

Coming across these guidelines reflect the EPA’s position in the Clean Air Act implementation. Under federal law as well as the state law, removing and replacing catalytic convertors is illegal and penalties are out there for those who do not abide by. Hence the effectiveness of aftermarket convertors lies on how long its duration goes, how well it performs as well as proper allocation so that it will meet the required standards.

It also imply to the installers to install only the past and approved convertors and only to the appropriate vehicles.

These programs establishment contain such factors like warranty, record keeping requirements, as well as reporting. Therefore, doing this gives the government a big possibility to strengthen and reinforce the requirements of ensuring the equality between car owners and the manufactures or installers.

Wednesday, May 22, 2013

Global Issues

A vehicle in any kind is believed to be one of the crucial contributors to global warming as it generated approximately more emissions. For example; in the United States, transportation provides more than one third of carbon dioxide emission and thirty percentages (30%) of America’s total global warming emission. In accordance to the project we work on, there is an impact globally as it will influence both the environment and the health of the people.

Regardless of the advantages biodiesel produced, there are also issues to be considered as they have an impact on the way we live. For example; no matter how different the standards are defined by the Americans and the Europeans with a big competition of its high derived petroleum, it is accountable in the renewing of most carbon atoms, the domestic use of origins, the decreasing of most regulated exhaust emission, biodegradability and so forth, it has a negative side to be taken into account as they are very sensitive issues and should be well taken care off. For example; there are problems being associated with biodiesel like oxidative stability due to its content of unsaturated fatty acid chains, poor cold flow and a slight increase of nitrogen oxide (NOx) exhaust emission in many emission test. Sometimes the problem fades due to the increase market penetrations of the new exhaust emission technologies alleviating this effect. Therefore the issue of improving biodiesel especially in terms of oxidative stability and cold flow is of great significance.

Bio fuels help lessen the effect of the emission of various pollutants in the atmosphere as it does not add carbon dioxide in the atmosphere, it just recycle what is already there.

Environmental Effects

In accordance to our, the problem being diagnosed is that the pipe can’t resist the airflow and from this add a great effect on the environment. This impact influenced both the green lush environment and the people. The more gas being released into the atmosphere, the increase the problem will be and the need is to lessen and diminish such problem. Effects on the environment is clear as we all understand, distinguished animals and plants will be extinguish and lost or even gone forever.

People will be facing various kinds of diseases and ways to cure these diseases will be hard to find, kids will even face malnutrition and a major effect will be on developing countries. So it is very important to understand every single circumstance of impact of installing, buying, selling and reusing any renewable resource.

The manufactures must feel aware and have a great concern to reduce exhaust emission and allow the vehicles to meet allocated standards or guidelines for a better and a healthy environment. In America it has a society called EPA or Environment Agency Protection which implement typical standards for the protection of the environment. In these standards they clearly explain all the policies a person has to follow and understand with before installing aftermarket convertors.

Since the effectiveness of the converters depends on their durability, performance and proper application, Environment Protection Agency required aftermarket convertors to meet certain minimum performance standards while also requiring installers to install the appropriate and proper convertors. It is very important for the installers to install correct convertor type for it operate effectively and not harmfully influencing the performance of the vehicle or even its emission control system.

The Environmental Agency Protection implement a fact sheet with answers to some of the common questions in which people may asked concerning the using of exhaust system, what is to be done legally and what should not be, and it’s all for the amendment of a clean air and the environment protection. Under certain circumstances and conditions apply when either removing or installing convertors.

Countries implement their motor vehicle emission control programs where motor convertors have been utilised and recognised the need for aftermarket convertors to maintain the effectiveness of the program and especially the maintenance and the sustainability of a healthy environment. Clean Air Act Amendments in partnership with the Environment Protection Agency (EPA) seek greatest degree in emission achievable.

Wednesday, May 15, 2013

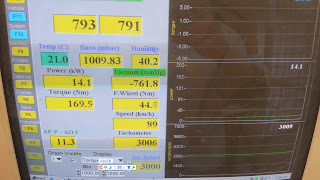

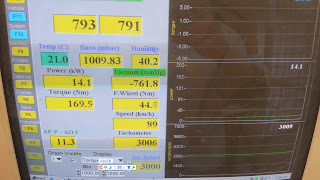

Variable de-cat pipe and Factory exhaust pipe tested on Dyno

Variable de-cat pipe and Factory exhaust pipe tested on Dyno

RPM De-cat exhaust pipe Factory exhaust pipe

Power (kw) Torque (N.m) Power (kw) Torque (N.m)

2588rpm

10.6kw

148.8N.m

10kw

139.5N.m

2999rpm

23.9kw

288.8N.m

13.3kw

161.3N.m

3003rpm 24.8kw 299.1N.m 14.1kw 169.5N.m

The above table explain the results on the engine Dyno between the factory exhaust pipe when it is running without load as well as the outcome once load is applied by installing a de-cat pipe. This result was accomplished by setting in three different engine speed and comparison among power (km) and torque (N.m).

Wednesday, May 8, 2013

Measurement

Measurement At 3850 rpm

1: Position of the butterfly-1.9kΩ

2: Pressure gauge reading-5kpa

3: Temperature at -250˚C

4: Pressure different at P1and P2=490.5N/s2 or 0.4905kpa

Manometer reading

3: Temperature at -250˚C

4: Pressure different at P1and P2=490.5N/s2 or 0.4905kpa

Manometer reading

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =50mm or 0.05m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.05m×1000kg/m3 ×9.81m/s 2

P= 490.5kg/ms2

N= (kg.m)/s2

P=490.5kg/ms2×N/kg.m/s2

P=490.5N/s2 or 0.4905kpa

Measurement

At 4300 rpm

1: Position of the butterfly-2.69kΩ

2: Pressure gauge reading-6.8kpa

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =50mm or 0.05m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.05m×1000kg/m3 ×9.81m/s 2

P= 490.5kg/ms2

N= (kg.m)/s2

P=490.5kg/ms2×N/kg.m/s2

P=490.5N/s2 or 0.4905kpa

Measurement

At 4300 rpm

1: Position of the butterfly-2.69kΩ

2: Pressure gauge reading-6.8kpa

3: Temperature at -260˚C

4: Pressure different at P1and P2=539.55N/s2 or 0.539kpa

Manometer reading

3: Temperature at -260˚C

4: Pressure different at P1and P2=539.55N/s2 or 0.539kpa

Manometer reading Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =55mm or 0.055m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.055m×1000kg/m3 ×9.81m/s 2

P=539.55kg/ms2

P=539.55kg/ms2×N/kg.m/s2

P=539.55N/s2 or 0.53955kpa

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =55mm or 0.055m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.055m×1000kg/m3 ×9.81m/s 2

P=539.55kg/ms2

P=539.55kg/ms2×N/kg.m/s2

P=539.55N/s2 or 0.53955kpa

3: Temperature at -250˚C

4: Pressure different at P1and P2=490.5N/s2 or 0.4905kpa

Manometer reading

3: Temperature at -250˚C

4: Pressure different at P1and P2=490.5N/s2 or 0.4905kpa

Manometer reading

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =50mm or 0.05m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.05m×1000kg/m3 ×9.81m/s 2

P= 490.5kg/ms2

N= (kg.m)/s2

P=490.5kg/ms2×N/kg.m/s2

P=490.5N/s2 or 0.4905kpa

Measurement

At 4300 rpm

1: Position of the butterfly-2.69kΩ

2: Pressure gauge reading-6.8kpa

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =50mm or 0.05m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.05m×1000kg/m3 ×9.81m/s 2

P= 490.5kg/ms2

N= (kg.m)/s2

P=490.5kg/ms2×N/kg.m/s2

P=490.5N/s2 or 0.4905kpa

Measurement

At 4300 rpm

1: Position of the butterfly-2.69kΩ

2: Pressure gauge reading-6.8kpa

3: Temperature at -260˚C

4: Pressure different at P1and P2=539.55N/s2 or 0.539kpa

Manometer reading

3: Temperature at -260˚C

4: Pressure different at P1and P2=539.55N/s2 or 0.539kpa

Manometer reading Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =55mm or 0.055m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.055m×1000kg/m3 ×9.81m/s 2

P=539.55kg/ms2

P=539.55kg/ms2×N/kg.m/s2

P=539.55N/s2 or 0.53955kpa

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =55mm or 0.055m

N= (kg.m)/s2

Pressure of fluid= P= h. ρ.g

P=0.055m×1000kg/m3 ×9.81m/s 2

P=539.55kg/ms2

P=539.55kg/ms2×N/kg.m/s2

P=539.55N/s2 or 0.53955kpa

Wednesday, May 1, 2013

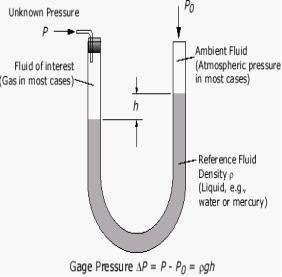

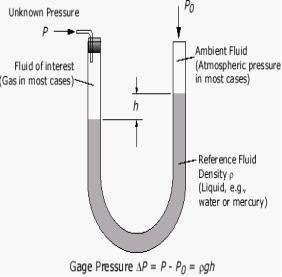

Construction of manometer

A manometer can be built by filling a clear plastic tube with a coloured liquid to allow the fluid level to be easily observed. The tube is then bent into a U-shape and fixed in an upright position. The levels of the fluid in the two vertical columns should be the same or equal, as they are currently exposed to the same pressure. This level is therefore marked and identified as the zero point of the manometer. The manometer is placed against a measured scale to allow any difference in the height of the two columns. This height differential can be used directly to make relative comparisons between different test pressures. This type of manometer can also be used to calculate the absolute pressure when the density of the liquid in the manometer is known.

Calculation

The pressure exerted by a column of fluid can be given by the equation P = h.ρ.g this equation, P is the calculated pressure, h is the height of the fluid, g is the force of gravity and ρis density of the water. Because the manometer is measuring a pressure differential rather than an absolute pressure, we use the substitution P = Pa - P0. In this substitution, Pa is the test pressure and P0 is the reference pressure.

Formula;

Pressure=F/A, Volume=h.A, ρ=m/v orifice diameter=2.1cm or 0.021m

Pressure of fluid= P= h. ρ.g radius=D/2

N= (kg.m)/s2

Force of gravity= 9.81m/s2

Density of water=1000kg/m3

Measurement

At 3230

1: butterfly position-1.82kΩ

2: Pressure gauge reading-3Kpa

Calculation

The pressure exerted by a column of fluid can be given by the equation P = h.ρ.g this equation, P is the calculated pressure, h is the height of the fluid, g is the force of gravity and ρis density of the water. Because the manometer is measuring a pressure differential rather than an absolute pressure, we use the substitution P = Pa - P0. In this substitution, Pa is the test pressure and P0 is the reference pressure.

Formula;

Pressure=F/A, Volume=h.A, ρ=m/v orifice diameter=2.1cm or 0.021m

Pressure of fluid= P= h. ρ.g radius=D/2

N= (kg.m)/s2

Force of gravity= 9.81m/s2

Density of water=1000kg/m3

Measurement

At 3230

1: butterfly position-1.82kΩ

2: Pressure gauge reading-3Kpa

3: Temperature at -240˚C

4: Pressure different at P1and P2=19.62N/m2or 0.01962 Kpa

Manometer reading

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =2mm or 0.002m

N= (kg.m)/s2

Pressure of fluid= P= h.ρ.g

P=0.002m×1000kg/m3×9.81m/s2

P=19.62kg/ms2

N=kg/ms2

P=19.62kg/ms2× N/kg.m/s2

P=19.62N/m2or 0.01962kpa

3: Temperature at -240˚C

4: Pressure different at P1and P2=19.62N/m2or 0.01962 Kpa

Manometer reading

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =2mm or 0.002m

N= (kg.m)/s2

Pressure of fluid= P= h.ρ.g

P=0.002m×1000kg/m3×9.81m/s2

P=19.62kg/ms2

N=kg/ms2

P=19.62kg/ms2× N/kg.m/s2

P=19.62N/m2or 0.01962kpa

Calculation

The pressure exerted by a column of fluid can be given by the equation P = h.ρ.g this equation, P is the calculated pressure, h is the height of the fluid, g is the force of gravity and ρis density of the water. Because the manometer is measuring a pressure differential rather than an absolute pressure, we use the substitution P = Pa - P0. In this substitution, Pa is the test pressure and P0 is the reference pressure.

Formula;

Pressure=F/A, Volume=h.A, ρ=m/v orifice diameter=2.1cm or 0.021m

Pressure of fluid= P= h. ρ.g radius=D/2

N= (kg.m)/s2

Force of gravity= 9.81m/s2

Density of water=1000kg/m3

Measurement

At 3230

1: butterfly position-1.82kΩ

2: Pressure gauge reading-3Kpa

Calculation

The pressure exerted by a column of fluid can be given by the equation P = h.ρ.g this equation, P is the calculated pressure, h is the height of the fluid, g is the force of gravity and ρis density of the water. Because the manometer is measuring a pressure differential rather than an absolute pressure, we use the substitution P = Pa - P0. In this substitution, Pa is the test pressure and P0 is the reference pressure.

Formula;

Pressure=F/A, Volume=h.A, ρ=m/v orifice diameter=2.1cm or 0.021m

Pressure of fluid= P= h. ρ.g radius=D/2

N= (kg.m)/s2

Force of gravity= 9.81m/s2

Density of water=1000kg/m3

Measurement

At 3230

1: butterfly position-1.82kΩ

2: Pressure gauge reading-3Kpa

3: Temperature at -240˚C

4: Pressure different at P1and P2=19.62N/m2or 0.01962 Kpa

Manometer reading

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =2mm or 0.002m

N= (kg.m)/s2

Pressure of fluid= P= h.ρ.g

P=0.002m×1000kg/m3×9.81m/s2

P=19.62kg/ms2

N=kg/ms2

P=19.62kg/ms2× N/kg.m/s2

P=19.62N/m2or 0.01962kpa

3: Temperature at -240˚C

4: Pressure different at P1and P2=19.62N/m2or 0.01962 Kpa

Manometer reading

Density of water=1000kg/m3

Force of gravity= 9.81m/s2

Height (h) =2mm or 0.002m

N= (kg.m)/s2

Pressure of fluid= P= h.ρ.g

P=0.002m×1000kg/m3×9.81m/s2

P=19.62kg/ms2

N=kg/ms2

P=19.62kg/ms2× N/kg.m/s2

P=19.62N/m2or 0.01962kpa

Wednesday, April 24, 2013

RPM-testing point

As we all know we install a throttle body in the middle of the pipe, the throttle body system as a piece of butterfly that we can control by the cable which connected to the throttle body of the 1UZ engine. The reason of why we still put the throttle position sensor (TPS) on is that we do not know how much angles of the butterfly moved.

The TPS sensor we used is from a TOYOTA 4AFE engine throttle body, it has 4 PIN in side, and they are +5 volts (positive), ground (negative), signal output, and reference.

At the first step we try to set up the +5v positive power and ground, then we used themultimeter test the signal output, but when we prepared everything it was hard to get the reading from the multimeter, so we give up this idea. In the next step we try to use the multimeter test the resistance of the TPS sensor.

We try to find the positive and negative first, the resistance between positive and negative is 4.24KΩ, next step we used an idea it called "method of exclusion". To connect one of the wire (positive or negative we do not know), other side connect to one the rest 2 PINS, if the reading is infinity which means the pin is the reference, we can leave it alone, if have the reading and when move the throttle body the reading change at the same time which means this PIN should be signal output. When it connects the positive and signal output and move the throttle body from closed (idle) to fully open, the reading is from 1.58KΩ ~3.89KΩ. The Revolutions Per/ Minute (RPM) we can test by the multimeter as well, to select the RPM gear and find out the tachometer transmitter, our supervisor show us where it is, as you can see in the photo

The TPS sensor we used is from a TOYOTA 4AFE engine throttle body, it has 4 PIN in side, and they are +5 volts (positive), ground (negative), signal output, and reference.

At the first step we try to set up the +5v positive power and ground, then we used themultimeter test the signal output, but when we prepared everything it was hard to get the reading from the multimeter, so we give up this idea. In the next step we try to use the multimeter test the resistance of the TPS sensor.

We try to find the positive and negative first, the resistance between positive and negative is 4.24KΩ, next step we used an idea it called "method of exclusion". To connect one of the wire (positive or negative we do not know), other side connect to one the rest 2 PINS, if the reading is infinity which means the pin is the reference, we can leave it alone, if have the reading and when move the throttle body the reading change at the same time which means this PIN should be signal output. When it connects the positive and signal output and move the throttle body from closed (idle) to fully open, the reading is from 1.58KΩ ~3.89KΩ. The Revolutions Per/ Minute (RPM) we can test by the multimeter as well, to select the RPM gear and find out the tachometer transmitter, our supervisor show us where it is, as you can see in the photo

.jpg)

The TPS sensor we used is from a TOYOTA 4AFE engine throttle body, it has 4 PIN in side, and they are +5 volts (positive), ground (negative), signal output, and reference.

At the first step we try to set up the +5v positive power and ground, then we used themultimeter test the signal output, but when we prepared everything it was hard to get the reading from the multimeter, so we give up this idea. In the next step we try to use the multimeter test the resistance of the TPS sensor.

We try to find the positive and negative first, the resistance between positive and negative is 4.24KΩ, next step we used an idea it called "method of exclusion". To connect one of the wire (positive or negative we do not know), other side connect to one the rest 2 PINS, if the reading is infinity which means the pin is the reference, we can leave it alone, if have the reading and when move the throttle body the reading change at the same time which means this PIN should be signal output. When it connects the positive and signal output and move the throttle body from closed (idle) to fully open, the reading is from 1.58KΩ ~3.89KΩ. The Revolutions Per/ Minute (RPM) we can test by the multimeter as well, to select the RPM gear and find out the tachometer transmitter, our supervisor show us where it is, as you can see in the photo

The TPS sensor we used is from a TOYOTA 4AFE engine throttle body, it has 4 PIN in side, and they are +5 volts (positive), ground (negative), signal output, and reference.

At the first step we try to set up the +5v positive power and ground, then we used themultimeter test the signal output, but when we prepared everything it was hard to get the reading from the multimeter, so we give up this idea. In the next step we try to use the multimeter test the resistance of the TPS sensor.

We try to find the positive and negative first, the resistance between positive and negative is 4.24KΩ, next step we used an idea it called "method of exclusion". To connect one of the wire (positive or negative we do not know), other side connect to one the rest 2 PINS, if the reading is infinity which means the pin is the reference, we can leave it alone, if have the reading and when move the throttle body the reading change at the same time which means this PIN should be signal output. When it connects the positive and signal output and move the throttle body from closed (idle) to fully open, the reading is from 1.58KΩ ~3.89KΩ. The Revolutions Per/ Minute (RPM) we can test by the multimeter as well, to select the RPM gear and find out the tachometer transmitter, our supervisor show us where it is, as you can see in the photo

.jpg)

Wednesday, April 17, 2013

Orifice calculation

Radius=D/2

r=0.055/2

r=0.0275

V= h ×

V=0.3 × π× 0.02752

V=7.13×10-4m3

Calculations above show the volume of the pipe which represents the volume flow of gas before encountering the orifices.

Radius=D/2

r=0.021/2

r=0.0105

V= h ×

V=0.006× 0.01052

V=2.078m3

Calculations above show the volume of the pipe which represents the volume flow of gas after encountering the orifices.

Radius=D/2

r=0.055/2

r=0.0275

V= h ×

V=0.3 × π× 0.02752

V=7.13×10-4m3

Calculations above show the volume of the pipe which represents the volume flow of gas before encountering the orifices.

Radius=D/2

r=0.021/2

r=0.0105

V= h ×

V=0.006× 0.01052

V=2.078m3

Calculations above show the volume of the pipe which represents the volume flow of gas after encountering the orifices.

Wednesday, April 10, 2013

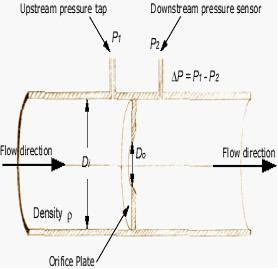

Pressure gauge and Straight 4 inch diameter pipe

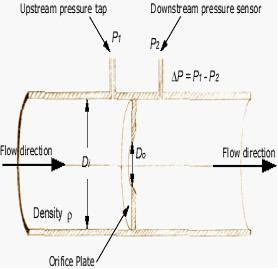

A back pressure gauge can be connected to the exhaust system one of several ways. By removing the oxygen sensor and connecting the gauge to the hole in the exhaust manifold by removing the air check valve in the air pump or plus air system, However on this design it is install on the pipe by drilling a hole just ahead of the butterfly to attach the gauge.

On the rear end of the straight pipe, a (orifice) 2.1 cm or 0.021mmwasher is weld inside the diameter of the exhaust pipe in addition with two tiny 3mm tubes. The pressure one is measured by the tube that is fitted just ahead of the washer or orifice while pressure two is measured by the second tube which is located just after the air flow is restricted by the orifice.

On the rear end of the straight pipe, a (orifice) 2.1 cm or 0.021mmwasher is weld inside the diameter of the exhaust pipe in addition with two tiny 3mm tubes. The pressure one is measured by the tube that is fitted just ahead of the washer or orifice while pressure two is measured by the second tube which is located just after the air flow is restricted by the orifice.

On the rear end of the straight pipe, a (orifice) 2.1 cm or 0.021mmwasher is weld inside the diameter of the exhaust pipe in addition with two tiny 3mm tubes. The pressure one is measured by the tube that is fitted just ahead of the washer or orifice while pressure two is measured by the second tube which is located just after the air flow is restricted by the orifice.

On the rear end of the straight pipe, a (orifice) 2.1 cm or 0.021mmwasher is weld inside the diameter of the exhaust pipe in addition with two tiny 3mm tubes. The pressure one is measured by the tube that is fitted just ahead of the washer or orifice while pressure two is measured by the second tube which is located just after the air flow is restricted by the orifice.

Wednesday, April 3, 2013

make manometer

Wednesday, March 27, 2013

air flow

gerry give us some idea today, he said we need test the air flow in the pipe, but the problem is the air flow meter can not test the exhaust air flow, because of the hot temperature, it will melt the meter, we can made a manometer instead of the air flow meter,but the first thing we have to do is install a ring in the pipe, and weld another two small tubes on each side of the ring.

Wednesday, March 20, 2013

install the pressure gauge and welding the gasket&adapter

today we still working in the workshop, we weld the gasket to the pipes and join to the adapter, also we weld the tubes on the pipe to connect the pressure gauge. as you can see in the photo, i bought the gauge from rosebank road, it really different to find the gauge, at first we went to repco, but they do not have the gauge, then we went to the BOC gas, they have the different gauge that we can not used, after that i went the rosebank road there is shop called "black..." ,i bought a pair cost 76 dollars. i am so happy i can find the gauge.

Subscribe to:

Comments (Atom)